Standardized machine installation and commissioning is the basis to ensure the good use of new instruments, play a performance, extend the life of the instrument.

The analytical instrument is composed of precision machinery and other components. The wear, corrosion and other factors caused by long-time operation will lead to incomplete function and performance degradation of the instrument. These problems may be occurring in the laboratory, which will affect the working efficiency of the customer and the life of the instrument. Therefore, it is essential to take positive countermeasures.

The maintenance service provides special cleaning, calibration, lubrication and testing for the instrument, as well as replacement of easily worn parts, so as to achieve the best state of the instrument through rigorous and scientific procedures. Help customers obtain accurate and stable analysis results, minimize unplanned downtime and improve work efficiency.

There is no charge for repairs within warranty but not included equipment failures and damage due to customer reasons (common conditions: faulty operation, bad environment), excluding consumables.

We can provide specialized product upgrading and technical transformation services according to the specific needs of customers.

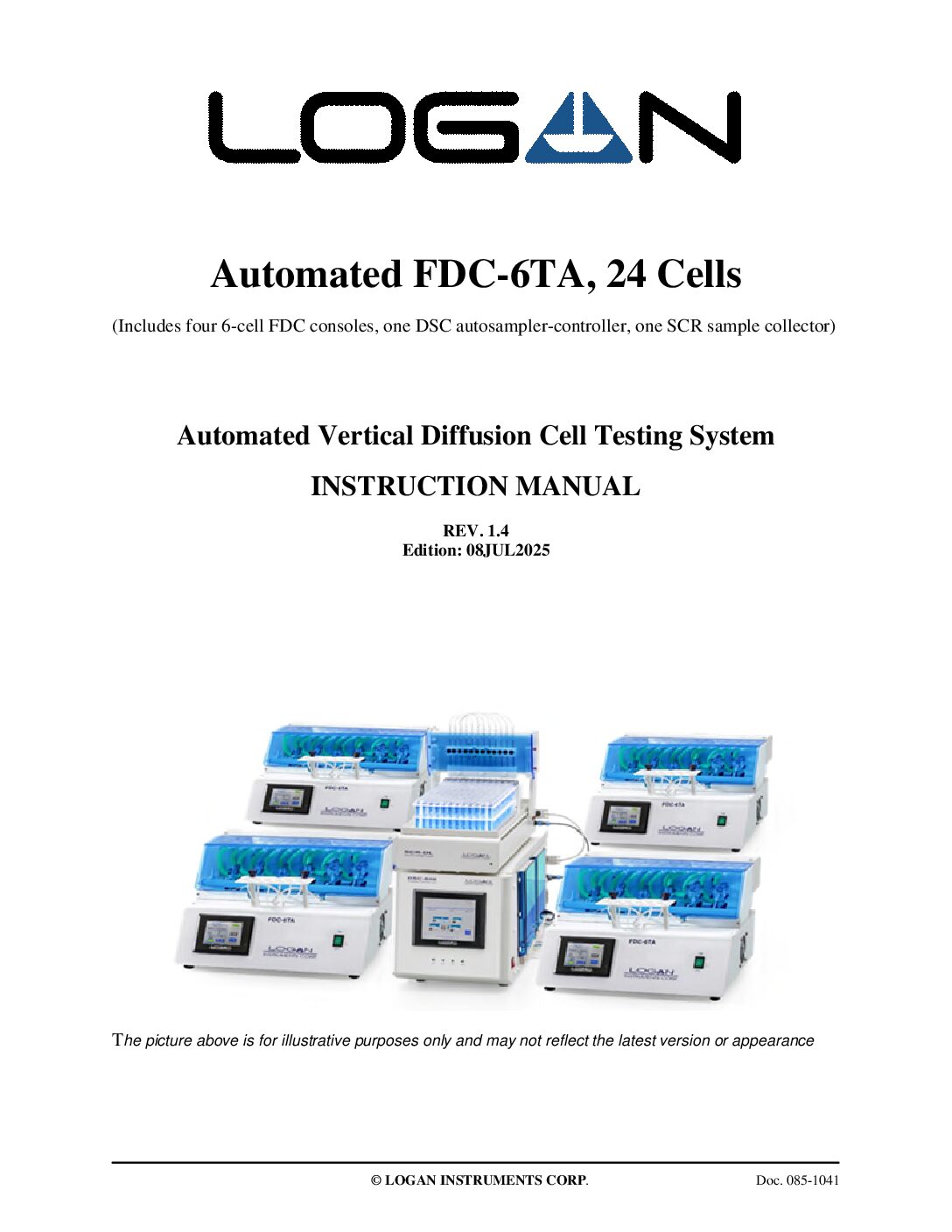

Many years of experience accumulated in the industry, LOGAN team for unique customers to provide specific personalized needs, which are covering from technical parameters customization, design, research, and development, to provide customers with high satisfaction, precision and specialized experimental equipment.

In the regulatory industry, it is necessary to ensure that your system has been installed and its function conforms to the manufacturer’s target use in order to better comply with government and international standards. Document verification is required. Whether you need installation certification, operation certification (IQ/OQ) or instrument performance verification (PVT), our certification service can provide data that meets the audit quality requirements and share it with your regulatory agency, And ensure that your instrument operates according to the manufacturer’s regulations. It can also provide valuable services for laboratories in unregulated environments, ensure that your instruments run well and can generate high-quality data, and make you more confident

Installation certification IQ: IQ procedures can ensure that the instrument has been provided and installed in accordance with the strict provisions of the setting, including transport integrity, system components and system configuration compatibility documents

We recommend that you perform IQ service at the following time:

- Instrument installation

- When the instrument is moved to another location or laboratory

- After the system adds functions (such as hardware or software upgrades)

- After adding components to the system

Operation confirmation OQ/instrument performance certification PVT, we recommend you perform OQ/PVT service at the following time:

- Instrument installation

- Regularly according to your standard operating procedures

- After overhaul

- After the instrument is moved to another laboratory

- After the system adds functions (such as hardware or software upgrades)

- After software changes affecting system security, data integrity or management control

2. Specific service requirements of customers:

Please contact us, LOGAN company team will provide you with professional services

Please contact us, LOGAN team will provide you with professional services.

Training

We provide training for all of the latest Logan instruments. LOGAN’s facility provides in-house training which offers a wide range of courses (i.e., Instrument operations to advanced applications and instrument maintenance courses). The course covers essential product working principle, fault technical troubleshooting, data analysis, and software training. After completing the course, you will be able to use this new knowledge to improve instrument usage and performance, expand its application, and establish more efficient experimental processes.

LOGAN selects qualified agents and provides training services around the world every year to help them provide local customers with the highest quality, professional and rapid response services: such as customer issues consulting, after-sales technical support and so on. According to the customer’s availability, LOGAN offers workshops so that the end-users and distributors have sufficient hands-on experience.

LOGAN has worked over the years to develop the drug dissolution systems. With years of developing these systems, we have acquired a wealth of experience in this field. As part of our service to our valued customers, we can lend our expertise in the in-vitro drug release method development. Please contact Logan for more information.